Do you want Total Productive Maintenance Questions? Casestudyhelp.net is the most trusted assignment writing service provider. They cover all kinds of tasks, such as case studies, thesis, essays, and dissertations, at an affordable price. With our subject matter expert, you get AI-free and pilgrims-free customized content or 24/7 live chat support.

QUESTION 1

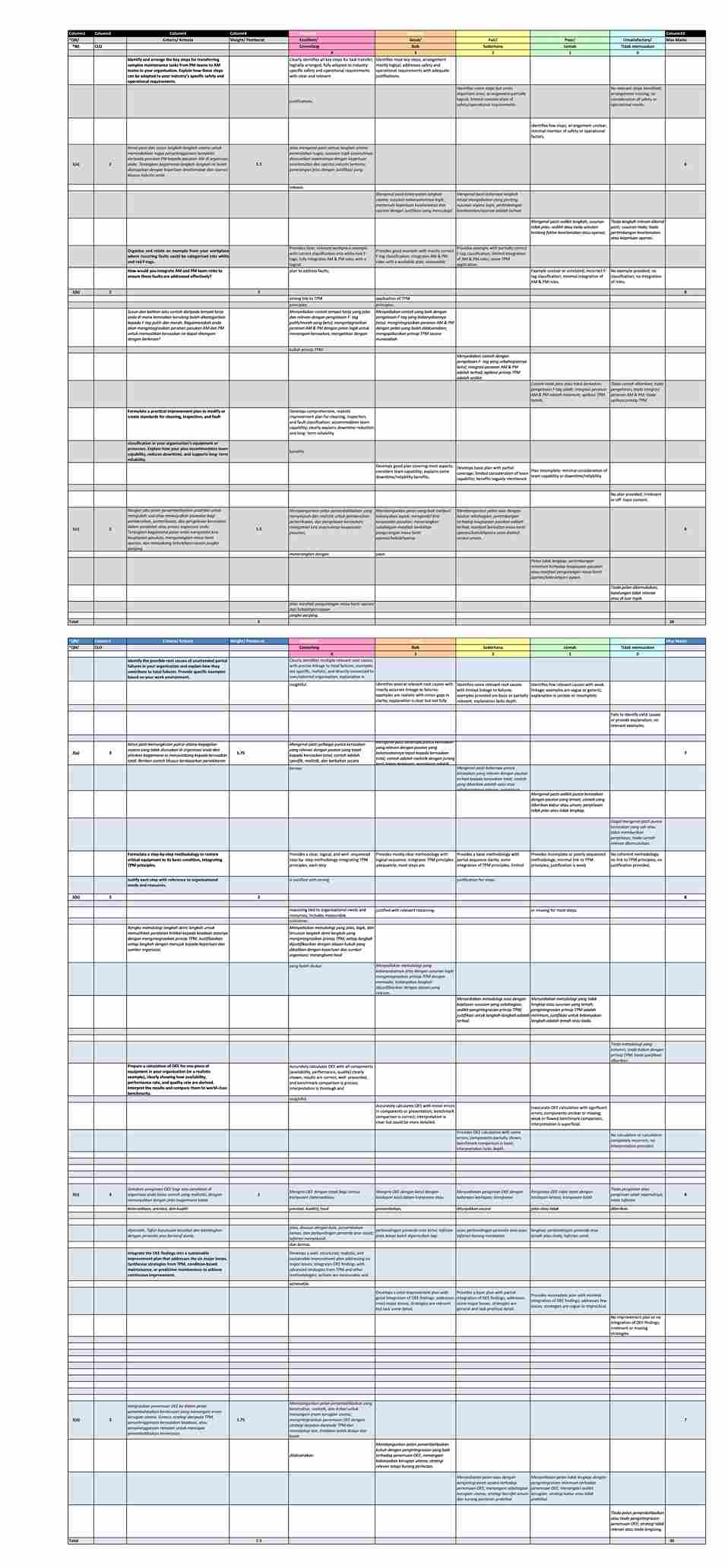

You are part of the maintenance improvement committee in your organisation. Recently, recurring equipment faults have been affecting productivity and service delivery. Management has decided to implement a Total Productive Maintenance (TPM) approach, focusing on creating standards and preparing for Autonomous Maintenance (AM).

As part of this initiative, both AM and Preventive Maintenance (PM) teams need to define responsibilities, create F-tag embedding spreadsheets, and establish safe and effective task transfer procedures. Your role is to contribute to this process by integrating your knowledge of TPM principles with your organisation’s current practices.

- Identify and arrange the key steps for transferring complex maintenance tasks from PM teams to AM teams in your organisation. Explain how these steps can be adapted to your industry’s specific safety and operational requirements.

- Organise and relate an example from your workplace where recurring faults could be categorised into white and red F-tags. How would you integrate AM and PM team roles to ensure these faults are addressed effectively?

- Formulate a practical improvement plan to modify or create standards for cleaning, inspection, and fault classification in your organisation’s equipment or processes. Explain how your plan accommodates team capability, reduces downtime, and supports long-term

QUESTION 2

You are appointed as a Maintenance Improvement Officer in a medium-to-large organisation that operates critical equipment across multiple sites. A recent internal audit reveals the following issues:

- Partial failures are often left unattended, resulting in frequent total

- Equipment is not being maintained at its basic condition, leading to reduced performance and increased defects.

- OEE (Overall Equipment Effectiveness) scores have fallen below industry benchmarks, with availability, performance, and quality all affected.

Management has tasked you with leading a project to restore equipment to its basic condition, eliminate the six major losses, and set a “Best of the Best” OEE goal. Your recommendations must be practical, measurable, and applicable to your own organisation or an organisation you are familiar with.

- Identify the possible root causes of unattended partial failures in your organisation and explain how they contribute to total Provide specific examples based on your work environment.

- Formulate a step-by-step methodology to restore critical equipment to its basic condition, integrating TPM principles. Justify each step with reference to organisational needs and

- Prepare a calculation of OEE for one piece of equipment in your organisation (or a realistic example), clearly showing how availability, performance rate, and quality rate are Interpret the results and compare them to world-class benchmarks.

- Integrate the OEE findings into a sustainable improvement plan that addresses the six major losses. Synthesise strategies from TPM, condition-based maintenance, or predictive maintenance to achieve continuous improvement.

ATTACHMENT

EBPM4103 TOTAL PRODUCTIVE MAINTENANCE /SEPTEMBER 2025